LONGEVITY

DURABILITY

QUALITY

TRUSTED

PROTECTIVE

COATINGS

At Mountain Protective Coatings, we take pride in delivering top-notch pipeline protective coating solutions tailored to meet the toughest industry standards.

Our range of products includes Primer Paste, Profiling Mastic, Petroleum Wax Tape, and Fiberglass Outerwrap, all designed to enhance the durability and longevity of pipeline systems.

With years of experience and a commitment to quality, we ensure that your pipelines receive the maximum protection they deserve.

Trust us to safeguard your investments.

PETROLATUM WAX TAPE

PEAK LT Petrolatum Wax Tape has been developed for long term protection of metal surfaces that are underground, underwater or otherwise exposed.

Additional mechanical protection is offered when PEAK LT Petrolatum Wax Tape is used in conjunction with PEAK Fiberglass Outerwrap.

PRIMING PASTE

PEAK LT Priming Paste is a proprietary substrate primer that displaces moisture, pacifies oxides, and fills small irregularities prior to wrapping with the PEAK LT Petrolatum Wax Tape system.

PROFILING MASTIC

PEAK LT Profiling Mastic is a petroleum based moldable compound designed to fill gaps, voids and irregular shapes prior to the application of PEAK LT Petrolatum Wax Tape.

Common uses include smoothing the irregular shapes and contours of valves, flanges bolts and any irregular shape. PEAK LT Profiling Mastic is a self-supporting compound that doesn’t harden, is chemically inert and resistant to moisture.

MOUNTAIN PROTECTIVE COATINGS

At Mountain Protective Coatings, we take pride in delivering top-notch pipeline protective coating solutions tailored to meet the toughest industry standards.

Our range of products includes Primer Paste, Profiling Mastic, Petroleum Wax Tape, and Fiberglass Outerwrap, all designed to enhance the durability and longevity of pipeline systems.

With years of experience and a commitment to quality, we ensure that your pipelines receive the maximum protection they deserve.

Trust us to safeguard your investments.

Contact

info@mountain-pc.com

(604) 787-4085

© 2025 Mountain Protective Coatings

CEL-375

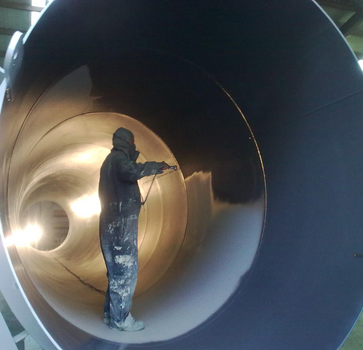

CEL-375 is a 100% solids epoxy that creates an extremely strong resilient protective film with excellent resistance to cathodic disbondment.

It is ideal coating protection for new pipe, fabricated assemblies, and rehabilitation of existing pipelines.

A two-component system applied directly to steel, CEL-375 is formulated to be spray applied with plural component heated airless pumps at a wet film thicknesses up to 60 mils DFT in a single application with excellent adhesion and abrasive characteristics. Brush Kits are also available.

Ideal for pipe, girth welds, valves, bends & field joints, CEL-375 is trusted for corrosion and mechanical protection against abrasive service conditions including horizontal directional drills (HDD) and slip bores.

With over 20 years meeting the needs of the pipeline industry, CEL-375 carries a wide-ranging and extremely successful track record.

Mountain Protective Coatings offers complete product application training according to the requirements of CSA Z245.30 & System FC7.

Our technical team is comprised of experienced pipeline coating applicators all with AMPP qualified coating inspectors numbers.

Contact MPC directly at info@mountain-pc.com or your local PEAK distributor.

CONTACT US

FIBERGLASS OUTERWRAP

Mountain Protective Coatings has partnered with CSNRI® utilizing SynthoGlass® pre-impregnated composite Outerwrap as the final layer of protection in our Petrolatum Wax Tape System.

PEAK / CNRI® SynthoGlass® Outerwrap provides industry leading abrasion and impact resistance, protecting a wide variety of parent and applied protective coatings.

FC-210

FC-210 High Performance Urethane Coating System is formulated for direct application and secure protection of metal substrates of mainline sections, new construction, and rehabilitation projects.

With excellent adhesion and resistance to cathodic disbondment, FC-210 provides monolithic membrane protection to the substrate of pipe, girth welds / field joints, elbows, Ts, transitions, fittings, bends, slip-bore / directional piping casings, carrier casings & valves.

FC-210 is a two-component, 100% solids, polyurethane coating system. It has been extensively tested (CSA Z245.20) for excellent adhesion and abrasion characteristics, with extremely quick turnaround time.

FC-210’s cold-temperature, fast-cure advantage has made it the “go to” coating solution of “winter dig” programs for over 20 years.